When I was doing some work on my tires one day, I noticed my sway bar link was broken. After hearing many people talk about disconnecting sway bars for off roading, I left alone. After taking a turn on the highway around 50 mph, I learned real quick what the sway bar on my jeep did.

So what does the sway bar on your Jeep do? A sway bar keeps your vehicle level by connecting the chassis and end links and thus preventing the body to roll to one side or the other when turning. When disconnected, the lack of sway bar allows maximum articulation from the suspension without causing the body to lean to extremes.

There are many styles of sway bars by several different companies. Some sway bars are designed to never be connected and others have fully adjustable links dependent on the size of lift you have.

Sway Bars and Sway Bar Links

Many, but not all, vehicles have sway bars to keep them level and from rolling while driving down the road. In fact, when driving on the road, sway bars are almost a complete necessity. It only takes on turn at the wrong speed in a Jeep to roll over.

Having a sway bar allows you drive your off-road monster like a normal car on the road. Depending on whether you use your Jeep for any kind of daily driving or if its strictly an off highway vehicle often is the deciding factor to keeping your sway connected.

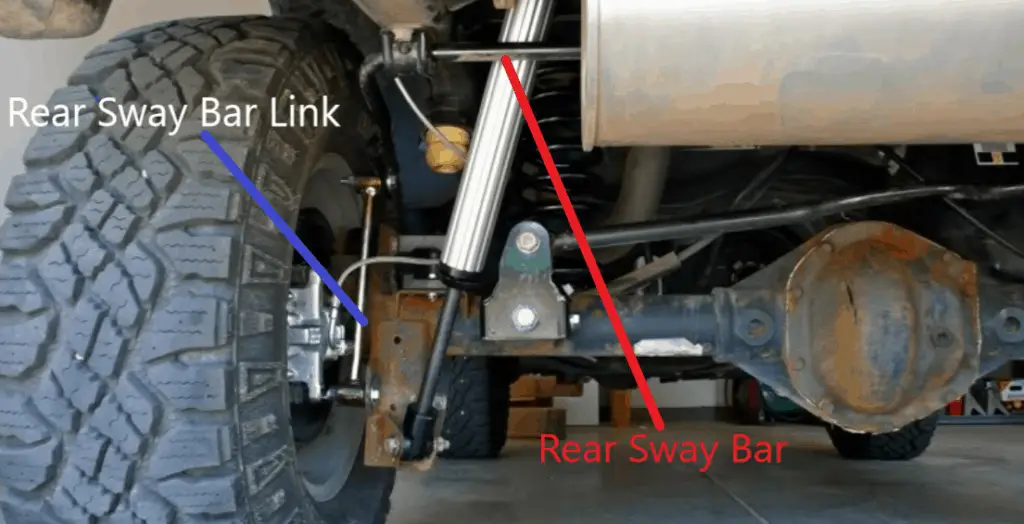

The sway bar and the sway bar links are two separate pieces. The sway bar links are the parts that actually connect the chassis to the sway bar and are often the pieces that brake or wear out, not your actual sway bar.

With lots of modern Jeeps, there are automatic sway bar disconnect switches built into the Jeep. So anytime you find yourself travelling off road, you push a button and you’re free to flex.

For those of us with older Jeeps or extreme off road builds, there are many options when it comes to how you want to connect/disconnect your sway bar or if you want to completely replace your sway bar.

One popular option that was started by Currie Enterprises is the Antirock Sway Bar system. Designed to never be disconnected, the Currie Anitrock acts as a big torsion bar. On road, it keeps the chassis connected as a normal sway bar.

When off road, it not only allows the suspension to flex, but also “pushes” on the side that is flexing. This allows the Jeep to move with the terrain and provide a much smoother ride.

The other option available, is to simply get new sway bar links. Not only are the factory sway bar links not designed for extreme off-road, they are useless and unsafe after any lift over 1.5″ is given to the vehicle.

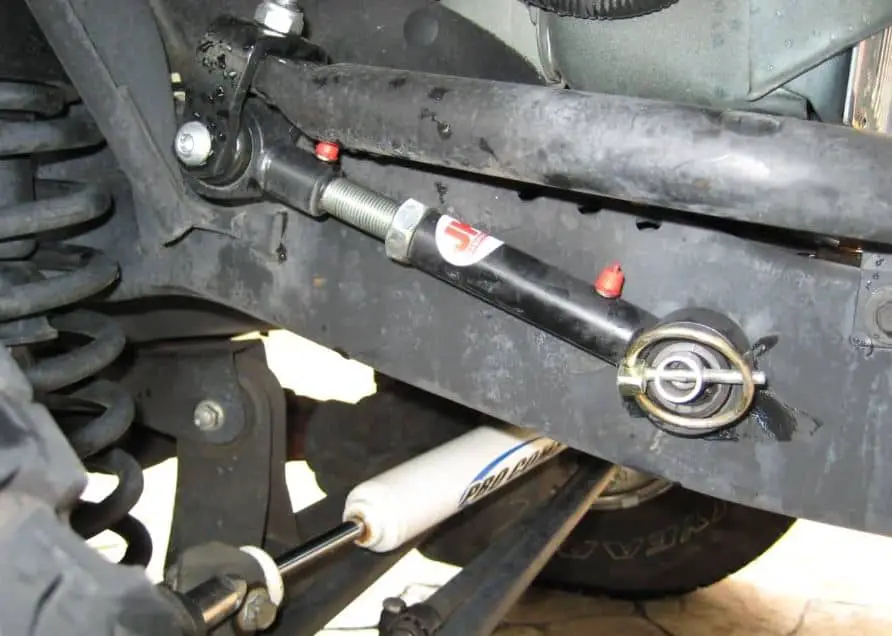

By replacing your factory sway bar links, you have the option to use an adjustable sway bar link like the JKS Adjustable Links.

These kind of links allow you to very easily connect and disconnect your sway bar depending on what you are doing. The JKS come with a convenient extra piece that allows you to pin the link up out of the way when not in use.

If you ever decide to lift or lower your Jeep, simply remove the link and adjust its height to compliment the amount of suspension lift you have on your vehicle.

Where is Your Jeep Sway Bar Located?

Jeeps are one of the vehicles that has two sway bars. One in the front and the other one in the back of the Jeep.

The front sway bar on your Jeep usually runs right beneath the bottom of your grill and across the front of the frame. It has two “L” shaped ends that face into the frame of the Jeep and are joined to the sway bar links.

The rear sway bar is nearly the exact opposite of the front. It runs across the far back end of the frame, and using the same shape as the front, connects via links to the appropriate axle connection.

Often times, it is not necessary to remove or disconnect the rear sway bar. While doing so provides the same benefits as disconnecting the front, you will notice much less benefits from the back. It is usually better to leave it connected for more stability.

How to Disconnect Your Sway Bar

Connecting and disconnecting your sway bars is really a simple process. Whether you have quick disconnects or not, the process shouldn’t take more than 5-10 min.

If you have quick disconnects similar to the JKS style, chance are you have a pin that you connect them to when aren’t connected to the sway bar. So all you have to do is get down where the link connects, pull the pin with a ring on it out, lift the link up and reconnect the link to the storage pin. Reference the picture below to see how it should look.

It is very important to have your sway bar links up and out of the way anytime they are disconnected. Otherwise they could get broken when off-roading or get caught in something.

If you don’t have quick disconnect system, whether electronic or manual, the process is very similar but requires having two sockets. These nut sizes are usually 12 mm or 1/2″ on some aftermarket systems.

Simply unbolt the nut that is holding the BOTTOM of the link to the axle connection. Using zip ties or similar, find a place to securely hold your link up and out of the way similar to the above picture of the JKS quick disconnects.

When Should You Disconnect Your Sway Bars?

Depending on the style of off-roading you find yourself doing most, you may never have to disconnect your sway bars. On the other hand, you might have to every time you leave the pavement.

Any kind of off-roading that requires you to maneuver over severely uneven surface will prove a better experience if you disconnect and allow your Jeep to flex happy and free.

If you are out with a group of people for an event or just hanging out, there is usually a time period before hitting the trails where owners are inspecting there rigs, letting air of their tires, and just getting ready for the day.

This is the perfect time for you to get underneath and disconnect your links. Even if you don’t have quick disconnects, there is plenty of time to break out the wrenches and sockets and get to work. Just don’t forget your tools.

If you are among the lucky ones who have electronic disconnects, then flip a switch, get a drink, and wait for everyone to finish up. Or help those less fortunate.

At the end of the day, there is usually a similar time period for everyone to air up their tires. Always make sure you reconnect your links at the end of the day if you plan on driving on the highway or pavement. This is often easy to forget and after a tiring day on the trails, the last thing you want is to roll on the highway after conquering much harder trails that day.

Related Questions

What are the Symptoms of Bad Sway Bar Links? Some common symptoms of failing or bad sway links include excessive rattling and clanking noises, lack of stability when driving, noise when hitting bumps in the road, and poor handling along with excessive roll when turning.

Is a Sway Bar the Same as a Stabilizer Bar? The purpose of these component is the same. However, certain design aspects may vary. Ultimately, they both help to stabilize the vehicle. Other common names for these components include anti-sway bars, anti-rocks, torsion bars, and anti-roll bars.

Is it Necessary to Replace Both Sway Bar Links? While it is not necessary, it is often encouraged and wise to replace both sway bars at the same time. Similar with many components, sway bar links should ideally wear out at the same rate. Therefore, replacing both at one time keeps them on the same “schedule” so to speak.